Fujian Qingtai Pipe Industry Technology Co., Ltd. is located in Lidun Industrial Park, Lidun Town, Zhouning County, Ningde City, Fujian Province. It was established in 2019. It is a comprehensive private enterprise that integrates the research and development, production, processing, and sales of stainless steel pipes. The stainless steel seamless pipe materials produced by the company include special alloy steel seamless pipes such as 300 series, 904, and duplex steel. The products include precision tubes, heat exchange tubes, BA tubes, and U-tubes. Widely used in industries such as petrochemicals, electricity, food, machinery, etc. The company is committed to providing customers with high-quality and reliable stainless steel seamless pipe products with advanced production equipment, exquisite technical team, and rich industry experience.

In 2023, the production capacity of hot-rolled coils has shown a simultaneous increase pattern in the past two decades. As of the end of 2023, the production capacity of hot-rolled coils reached 29.12556 million tons, with a growth rate of 11.01%. In 2023, the production of hot-rolled coils exceeded that of threaded steel (with a production of 260 million tons in 2023), making it the largest steel variety in China. In terms of annual production trends, the production of hot-rolled coils has been increasing year by year in the past five years, and the growth rate has increased from 2.57% in 2019 to 11.01% in 2023, an increase of 8.51 percentage points.

From the perspective of monthly production changes in 2023, in order to better analyze the historical position of monthly production in 2023, Zhuochuang Information used monthly production data of hot-rolled steel sheets and coils in the past 15 years. By selecting the highest and lowest values of each month, a fluctuation point map of hot-rolled steel sheet and coil production was created, as shown in Figure 2. From Figure 2, it can be seen that the monthly production of hot-rolled coils in 2023 is above the historical highest level. Due to the production growth rate reaching 11.01% in 2023, far exceeding the capacity growth rate by 3%, the capacity utilization rate of the hot-rolled plate and coil steel plant has increased to 84.7%, an increase of 6.11 percentage points from 2022. It can be seen from this that the market s high-yield model runs through the entire year.

The main reason for the high production of hot-rolled coils in 2023 is the achievement of new production capacity, high coil screw deviation, and steel mills switching to hot-rolled coils.

New production capacity put into operation, driving market supply to maintain growth momentum

In terms of the production situation of hot-rolled coils in 2023, a total of 4 new hot-rolled production lines were added, involving an additional production capacity of 10 million tons, with a capacity increase of 3%. Please refer to the "2023-2024 Annual Report on China s Hot Rolled Plate and Coil Market" for the new production capacity of steel mills in the hot rolled plate and coil market in 2023. Due to the fact that the newly added production capacity in 2023 is mainly concentrated in the first half of the year, as the production capacity reaches its capacity, the output will increase accordingly.

The spiral difference of the coil remains relatively high, and steel mills concentrate on spiral production to produce coils

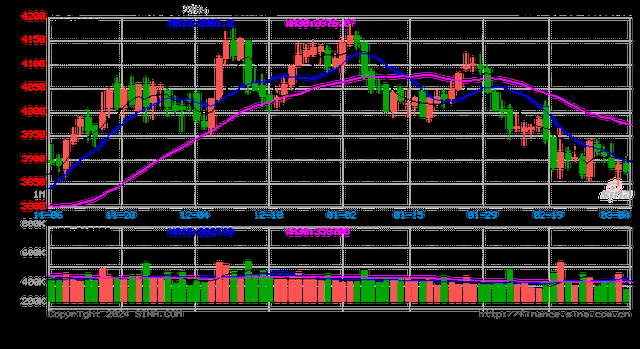

From the perspective of the price trend of coil coils in 2023, as shown in Figure 3, for most of the time, the coil coil difference was positive, and in April and July September 2023, the coil difference exceeded 150 yuan/ton. In this situation, the profits from producing hot-rolled coils in steel mills were more substantial. Driven by profits, it drove steel mills to concentrate on producing threaded steel and switch to hot-rolled coils, thereby maintaining a high level of hot-rolled coil production.

The high-yield model may continue to be maintained in 2024

The market supply situation in 2024 mainly considers the following points: firstly, the intervention of new production capacity will drive the continued increase in production; Secondly, the recovery of real estate is slow, and the related products of hot-rolled plates and coils, such as threaded steel, are difficult to improve. The spiral production of coils may continue to exist; Finally, the advanced rolling process of hot-rolled coils enhances the substitution effect on cold-rolled coils and medium thick plates.

In terms of new production capacity, according to the current statistics from Zhuochuang Information, there are expected to be 5 rolling lines with a total production capacity of 18.7 million tons put into operation in the 2024 hot rolled plate and coil steel plant. The intervention of new production capacity will further increase production.

In terms of related products, industry insiders have always made investment choices by comparing the changes in coil helix differences. However, in recent years, the coil helix differences have gradually expanded, with the highest coil helix difference reaching 310 yuan/ton in 2023. Against the backdrop of slow real estate recovery, the price of rebar has yet to improve, leading to a gradual expansion of coil helix differences. With the expansion of coil helix differences, steel mills have chosen hot-rolled coils with relatively good profit levels for production, thereby driving the market s trend of rebar production to hot-rolled coils. In 2024, the real estate industry has not shown any signs of improvement, and the transition to hot-rolled rebar production may become the norm.

In terms of replacing other products, with the centralized production of ESP rolling lines in the hot rolled plate and coil market, as well as the gradual improvement of rolling technology and market processing technology, cold formed products of hot rolled plate and coil play a good substitute role for cold rolled plate and coil, and hot rolled open plate plays a certain substitute role for medium and thick plate and thin plate. As a primary processed product of sheet metal, hot-rolled coils are more affordable than cold-rolled coils and medium thick plate products. Therefore, in areas where they can be replaced, downstream customers prefer hot-rolled coil products.

Based on the above points, it can be expected that the high-yield model of hot-rolled coils may continue to be maintained in 2024. However, considering the background of crude steel level control and the gradual slowdown in market demand growth, it is expected that the growth rate of hot-rolled coil production may gradually slow down.

As a 3 stainless steel pipe, safety is the main concern. Once the stainless steel pipe cracks, its protective performance will be greatly reduced. However, why does the stainless steel pipe crack and how can we prevent it

Stainless steel pipes are welded from steel plates, and the cracking of the weld seam is usually caused by grinding the weld seam too deeply, making it too thin during the processing. This is a quality problem and is not a qualified stainless steel pipe. If it is not used, this problem cannot be discovered. It is usually discovered after use, which also brings some trouble to our lives.

Therefore, attention should be paid to preventing fracture at the weld seam. So choosing stainless steel pipes with nitrogen protection is a good preventive method. Generally, stainless steel pipes without nitrogen protection are prone to rusting and cracking, and are more stable compared to nitrogen. They provide less cracking protection for the inner weld bead and can also effectively reduce the chance of rusting in stainless steel pipes.

In addition, when cutting stainless steel pipes, it is necessary to first confirm whether there are scratches on the pipes in order to check the quality of the incoming materials. If there are scratches, they should be returned and cannot be processed.

When bending stainless steel pipes, it is necessary to first check whether there are impurities or foreign objects on the upper and lower molds and the sheet metal. If there are, the bending operation cannot be carried out to prevent pressure damage to the stainless steel pipe. These are also areas that stainless steel pipes need to pay attention to to to prevent breakage

The production process of seamless steel pipes mainly includes the following steps:

a. Preparation of raw materials: Select suitable steel billets, requiring smooth surface, no bubbles, no cracks, and no obvious defects.

b. Heating: Heat the steel billet to a high temperature state to make it plastic and easy to form.

c. Perforation: The heated steel billet is pierced into a tube billet through a piercing machine, which is the preliminarily formed steel pipe.

d. Rolling tube: Rolling the tube blank multiple times to reduce its diameter, increase its wall thickness, and eliminate internal stress.

e. Sizing: The steel pipe is finally shaped using a sizing machine to meet the standard requirements for diameter and wall thickness.

f. Cooling: The solidified steel pipe is cooled to increase its hardness and strength.

g. Straightening: Straightening the cooled steel pipe to eliminate its bending deformation.

h. Quality inspection: Conduct quality inspection on finished steel pipes, including dimensions, wall thickness, hardness, surface quality, and other aspects